Servo unscrewing devices are DMEs answer to the demands made on high-performance injection molds with unscrewing functionality. Although moldmakers are always on the lookout.

Pdf Demolding Moment Calculation For Injected Parts With Internal Saw Thread

The molds become more compact and the number of cavities in the molds is.

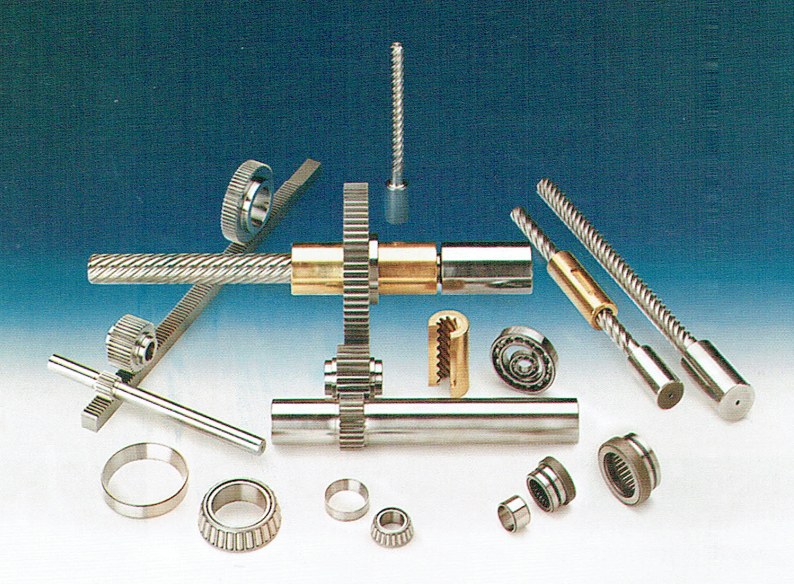

. Features The Threadformer unscrewing devices are precise sturdy and cost-efficient. This value is not based on the drive gear diameter which will be considered later. Mold Build Assembly 42-45 6.

Choosing unscrewing components for your molds shortens leadtimes reduces component costs and decreases cycle times. Quick Reference Checklists 59-64 8. Are runner gate location and type shown on the drawing.

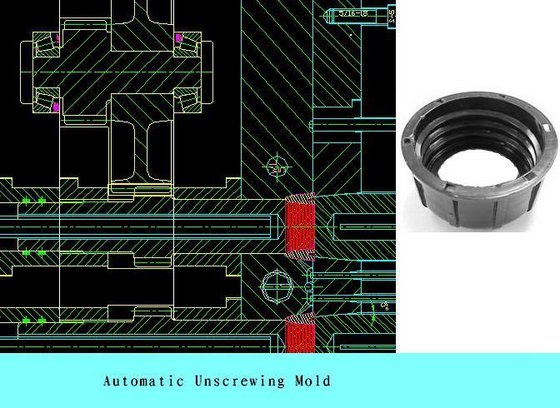

Advantages vs Unscrewing Molds. Injection molding cavity pressure. Several methods are used for unscrewing molds including hydraulic motors splines various gearing methods and for large multiple cavity.

In the parting plane design possibilities that are completely new for mold making can be obtained. Maintenance Repair 46-58 7. The design part of the mold is movable in nature and undertakes the shape of a mosaic.

Also referred to as unscrewing moulds. This amalgamation is important for facilitating the. Injection molded threads are stronger than tapped threads tighter.

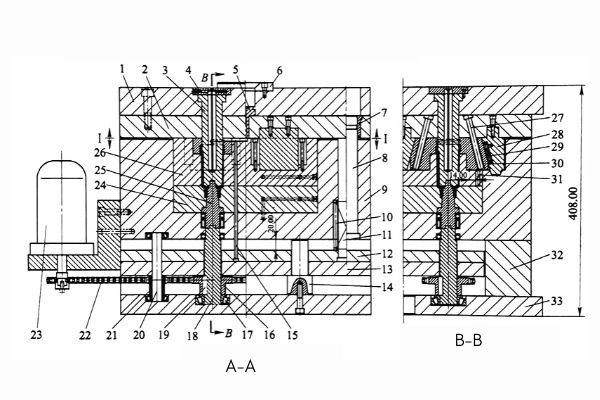

Design of the Automatic Unscrewing Mold. Mold Design 29-41 5. Check Pages 1-50 of INJECTION MOULD DESIGN in the flip PDF version.

Part size200000X200000X165000 Shrinkage rate10225 Cavitation size. INJECTION MOULD DESIGN was published by sureshkumars on 2017-09-15. Mold design has great impact on productivity and part quality.

CALCULATING THE UNSCREWING TORQUE FOR ONE CAVITY _____ D1. 5 Product and Mold Design 62 Proper design of the injection mold is crucial to producing a functional plastic component. We design internal and external threads in custom plastic parts during plastic molding process through unscrewing molds.

ENGINEERING DESIGN GUIDE D-M-E Hydraulic Unscrewing Device 20357 HUD DAG_rev 91206 436 PM Page 3. Unscrewing Mold Design for Protector. Plastic Injection Mold Design-Runner Gate System 31.

Unscrewing mold design with Sliders. Does the gate type match the mold design specification sheet. The informa tion contained in the guide lines will maximize the molds cycle time and improve part quality with the use of copper alloys in the.

Gating locations A consequence of gating a cup shaped component from the side is the formation of weld lines. Tion molder mold designer and mold builder. Collapsible cores or in unscrewing molds.

Compact and sturdy design Unscrews 70 mm Complete single unit Threadformer installation. 204500X204500X169125 Part weight1325kg Cavity weight14000kg. 2 Hydraulic Unscrewing Device Without guiding thread with cam.

Unscrewing mold design with Rotary Motor driver. Weld lines occur when flow fronts.

Unscrewing Injection Mold Design With Sliders Study Case Upmold

Auto Unscrewing Injection Mold Design Solutions Upmold

Automatic Unscrew Thread Injection Mold For Pipe Fitting

Automatic Unscrewing Mold Plastic Mold Id 6203765 Product Details View Automatic Unscrewing Mold Plastic Mold From Leeon Industry Development Limited Ec21

Unscrewing Plastic Mold Design With Rotary Driving Case Upmold

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

0 comments

Post a Comment